The evolution of semi-metallic brake pads is a testament to the significant advancements in material science that have transformed automotive braking systems over the decades. Originally developed as a solution to the limitations of organic brake pads, semi-metallic brake pads have become a critical component in modern vehicles, particularly for those requiring high-performance braking under demanding conditions. The progress in material science has been central to this evolution, driving improvements in performance, durability, and safety.

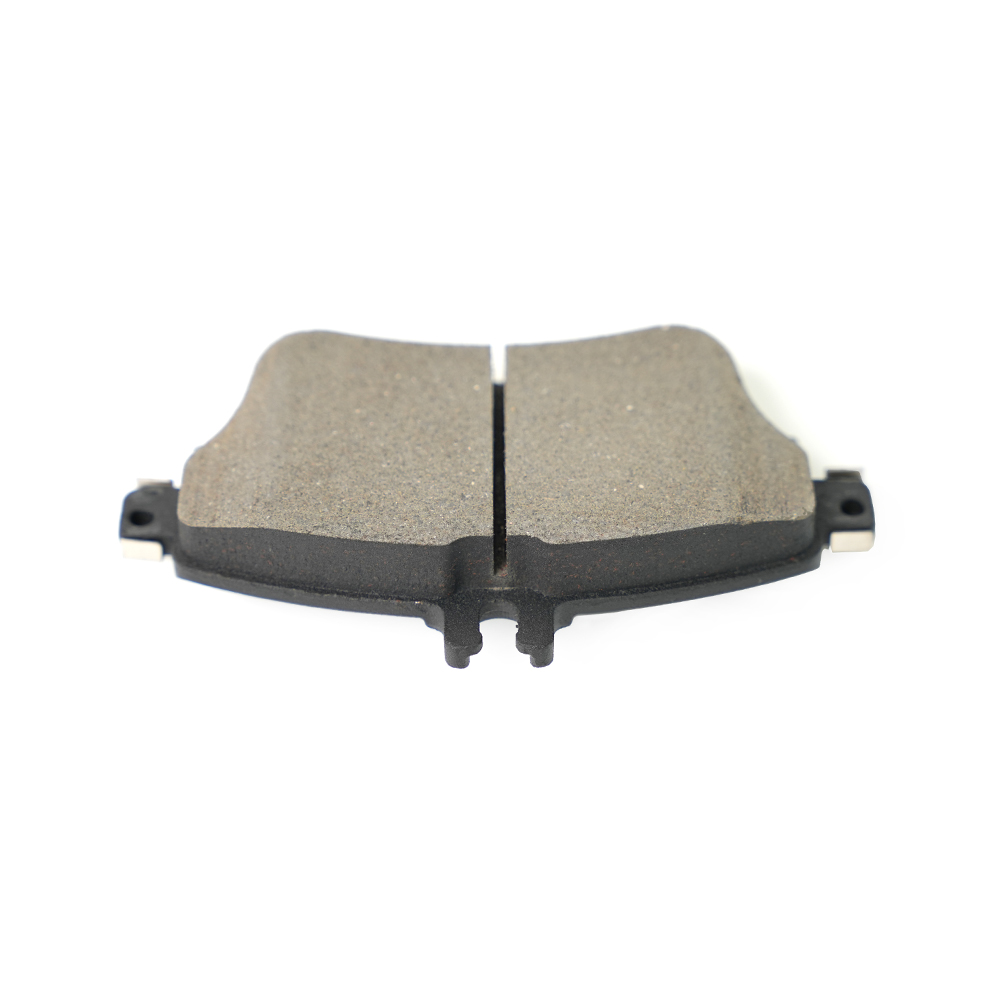

Semi-metallic brake pads are composed of a mix of metals, such as steel, iron, and copper, combined with graphite and other fillers. The early iterations of these pads were primarily designed to address the shortcomings of organic pads, which, while quieter and less abrasive, lacked the necessary heat dissipation and durability for high-performance or heavy-duty applications. Material science innovations have enabled the development of more sophisticated formulations that optimize the balance between friction, wear, and thermal management. The inclusion of metallic steel wool, for instance, has significantly enhanced the thermal conductivity of these pads, allowing them to dissipate heat more efficiently. This not only prevents overheating during intense braking but also contributes to the pad's overall durability, making them suitable for a wider range of vehicles, from daily drivers to high-performance models.

As material science advanced, the ability to fine-tune the composition of semi-metallic brake pads led to improvements in their friction coefficients. Modern semi-metallic pads, like those produced with isotropic compression molding techniques, exhibit a friction coefficient range of 0.38 to 0.42, providing consistent and reliable braking performance. These pads are engineered to maintain their friction properties across a broad range of temperatures, ensuring that braking performance remains stable even under extreme conditions. Additionally, the porosity of the pads, which averages around 5.5%, has been optimized to manage heat and resist fade, a common issue in earlier brake pad formulations. These advancements in material composition have made semi-metallic pads the preferred choice for vehicles requiring dependable stopping power, such as those with larger inertia or those used in heavy-duty applications.

The commercial value of semi-metallic brake pads has also been significantly influenced by material science. With the ability to produce pads that offer a moderate lifespan—ranging between 20,000 to 50,000 kilometers—manufacturers can provide a product that balances cost-effectiveness with performance. The moderate dust production and noise levels, while slightly higher than ceramic alternatives, are often seen as a fair trade-off for the enhanced braking power and thermal resistance that these pads offer. This is particularly true for users who prioritize safety and performance in their driving experience. For instance, the semi-metallic brake pads produced by your company, which include over 10% metallic steel wool, showcase these advancements. They provide excellent thermal conductivity, high-temperature resistance, and a sensitive braking response, making them ideal for both daily use and more demanding driving conditions.

Moreover, material science has played a crucial role in refining the manufacturing processes of these brake pads, such as the use of isotropic compression molding. This process ensures that each pad has uniform material properties, leading to consistent product performance. This consistency is critical for vehicles with larger inertia, where reliable and stable braking is a must. The ability to produce brake pads with such precision has not only improved the safety and reliability of vehicles but has also reduced the frequency of brake pad replacements, contributing to lower maintenance costs over the vehicle's lifetime.

The evolution of semi-metallic brake pads is deeply rooted in the advancements of material science, which have allowed manufacturers to develop products that offer superior performance, durability, and safety. These innovations have made semi-metallic pads an essential component in modern automotive braking systems, capable of meeting the diverse needs of drivers while maintaining a balance between cost and performance. Your company's semi-metallic brake pads exemplify these advancements, providing a reliable, high-performing solution that benefits from the latest material science breakthroughs.