Replacing semi-metallic brake pads is a task that requires both the right tools and a good understanding of the process. To ensure a successful replacement, you'll need a selection of specialized tools and equipment, each serving a distinct purpose in the procedure.

Firstly, a car jack and jack stands are essential. The jack is used to lift the vehicle, allowing access to the wheel assemblies where the brake pads are located. Once the vehicle is elevated, jack stands are placed under the vehicle for added safety, ensuring it remains stable during the replacement process. Additionally, a lug wrench or socket set is necessary for removing the wheel bolts. This tool allows you to take off the wheel, which is crucial for accessing the brake caliper and rotor.

Next, a brake caliper tool or C-clamp is needed to compress the caliper piston. This step is important because it creates enough space for the new brake pads to fit. Depending on the design of your brake system, you might also require a caliper wind-back tool for certain vehicles that have a screw-type caliper piston. Additionally, a socket set or wrench set will be needed to remove the caliper bolts, which hold the caliper in place over the brake rotor.

To ensure smooth removal and installation, a brake grease or anti-squeal lubricant is recommended. Applying this lubricant to the caliper slides and the back of the new brake pads helps reduce noise and ensures smooth operation. Moreover, a torque wrench is crucial for properly tightening the caliper bolts and wheel lug nuts to the manufacturer's specified torque settings, preventing any potential issues during driving.

While not always necessary, having a brake fluid and a bleeder kit on hand can be beneficial. During the brake pad replacement, you may need to check and top off the brake fluid level, and in some cases, bleeding the brake system might be required to remove any air bubbles that could affect brake performance.

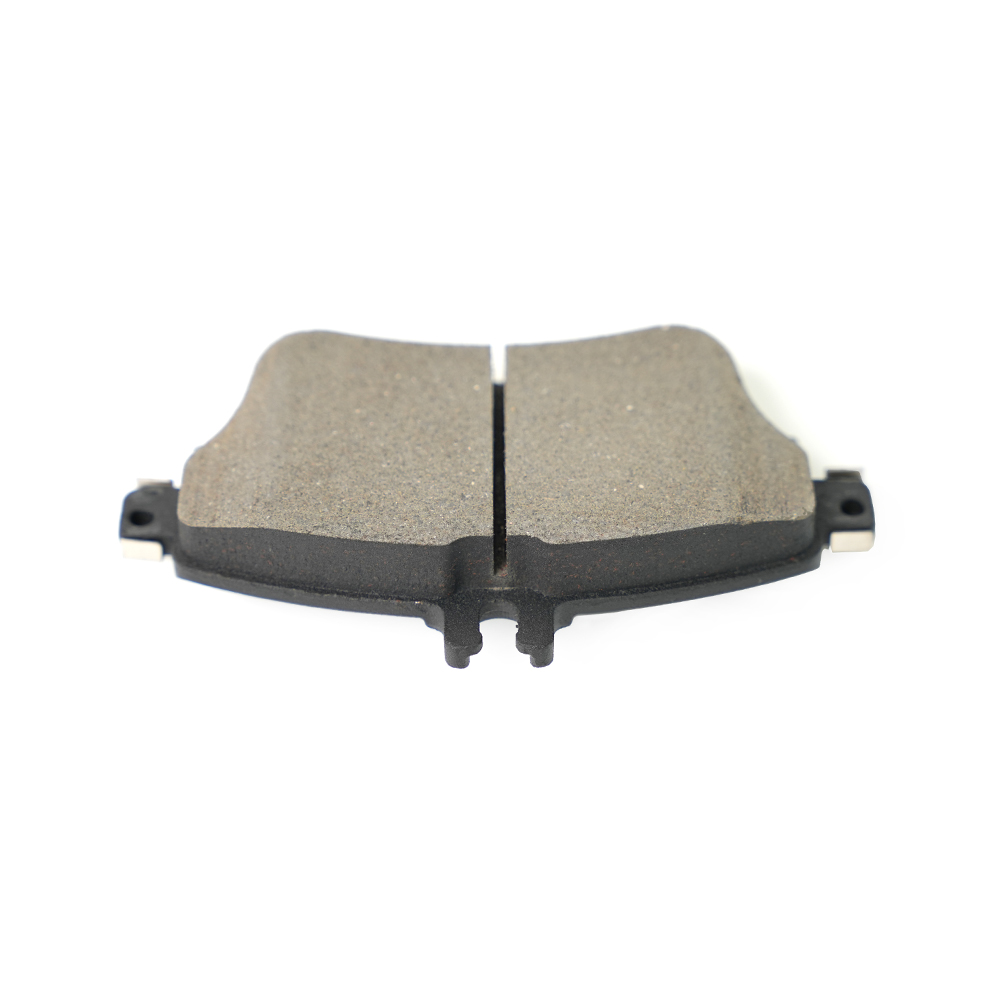

Finally, it’s always a good idea to have a brake pad wear gauge to measure the thickness of the old pads before replacement. This can provide insight into the wear patterns and help ensure that the new pads are installed correctly.

Replacing semi-metallic brake pads involves a combination of basic automotive tools and specific equipment designed for brake system maintenance. Ensuring you have these tools will facilitate a smoother, safer, and more efficient brake pad replacement, contributing to the continued reliability and performance of your vehicle's braking system.